Request A Quote

Request A Quote

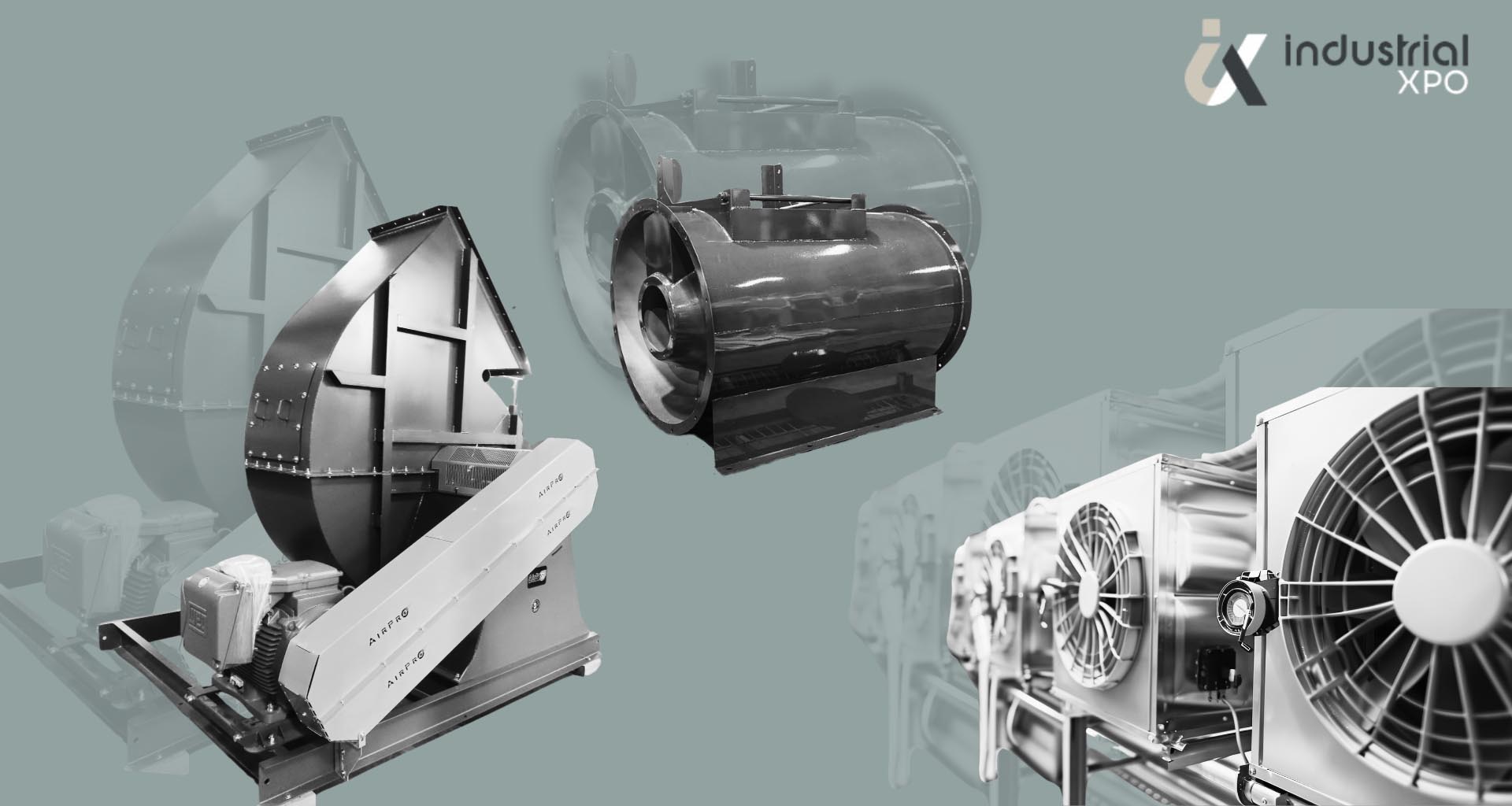

A fan is a fan is a fan…right? Not exactly. In the world of industrial fans, there are three types of fans overall. Each type has many design variations to fit the different application requirements of industrial manufacturing.

Centrifugal Fan: A centrifugal fan is designed to overcome high levels of system resistance (static pressure) and move air, gas, and/or materials through a system. Air enters the fan inlet in one direction, is rotated by the blades inside the fan to turn the air 90 degrees, and then exits the fan outlet in a perpendicular direction.

Axial Fan: An axial fan is open on both sides and moves air in the same direction at low static pressure. Think box fan - the air enters the fan from one side and continues in the same direction as it exits the fan on the opposite side.

Mixed Flow Fan: A mixed flow fan combines the characteristics of both centrifugal and axial flow fans. It generates a combination of radial and axial airflow, providing a higher-pressure output compared to an axial fan and higher airflow compared to a centrifugal fan.

Centrifugal Fans and Blowers - move lots of air at high pressures, and they are essential components in a wide range of industrial manufacturing systems. These systems often need to move air over long distances, in conjunction with other equipment, and through a maze of ductwork. Centrifugal fan designs can overcome the system resistance and push or pull air through dust collectors, cyclones, oxidizers, scrubbers, dryers, and many other types of industrial equipment systems. Some of the most common applications are:

Axial Fans - used throughout manufacturing facilities, warehouses, and other commercial buildings. Since they are not designed for high pressure, you will not find these fans connected to intricate systems and ductwork like centrifugal fans. Rather axial fans are mostly used to ventilate large areas and move air from one space to another. They are efficient and don’t require a lot of space. Common applications include:

Mixed-Flow Fans - include both centrifugal and axial design characteristics. They are designed for ducted applications with straight-through airflow where space is limited, low noise levels are important, and static pressures are higher than what axial fans can provide. They are used in institutional, commercial, and industrial settings. Typical applications include:

Whether you need centrifugal, axial, or mixed-flow fans, there are additional design factors to consider. They include size, wheel design, construction materials, arrangement, coatings, and more. To properly select and design your fan, you need to know how much airflow the fan needs to move, how much resistance (static pressure) the fan must overcome, and the density of the air going through the fan along with any other gases or material.

Whatever your fan needs are, we are here to help! With decades of experience with industrial fans, we will help you determine the best fan design for your application. We work with the top fan manufacturers in the industry and will outfit you with the fan that meets your needs, including budget and timeline.

Whatever your fan needs are, we are here to help! With decades of experience with industrial fans, we will help you determine the best fan design for your application. We work with the top fan manufacturers in the industry and will outfit you with the fan that meets your needs, including budget and timeline.

Reach out today to our team, and one of our application engineers will be happy to assist you.